It takes a lot of practice to produce a nice fillet braze around two tubes, coming together at interesting angles.

Last month I spent a week learning about bicycle frame construction at the country’s newest frame building school,

The Bicycle Academy. TBA was founded last year by Andrew Denham, with money raised in large part through a crowd funding exercise raising over £40,000 in under a week. I was one of these 183 initial backers, pre-booking a course with master frame builder Brian Curtis, Andrew and Chris Sheppard. The BBC have an article and video about TBA here:

http://www.bbc.co.uk/news/business-19286163

This was my third foray into the world of frame building, having previously

built a frame with

Dave Yates in Lincolnshire and attended a frame building workshop with

Dario Pegoretti in Verona, Italy. Each experience has been very different from the last and I’m starting to appreciate what Dave said to me about there being as many ways to build a frame as there are frame builders. In Frome we were fillet brazing with oxyacetylene, where with Dave I built a lugged frame and in Italy Pegoretti used propane for the fuel gas.

Acetylene is the fuel of choice, however, it's also highly volatile and demands a lot of respect.

The main focus at The Bicycle Academy, rather than to build your dream bicycle, is to learn the skills of frame building. The frames the two of us on the course would build were a standard design, the ‘Africa Bike’, which once completed would be donated through charities

Re-Cycle and

World Bicycle Relief. I had already taken a 1-day brazing masterclass with Brian a month earlier and it didn’t take long to get my eye in on a few test pieces. I was particularly proud of the practice bottom bracket mock-up:

Bottom bracket test piece. A lot of heat builds up in the BB which we have to learn to adjust for. Photo credit: A. Denham.

The workshop itself is a lovely environment, well lit with as much wall space given over to cycling artwork as the tool boards. This, along with the steady supply of biscuits and coffee make the space easy to work in whether brazing with all the protective gear on or just reading one of their library’s books on frame building, cycling heroes or more general metalwork.

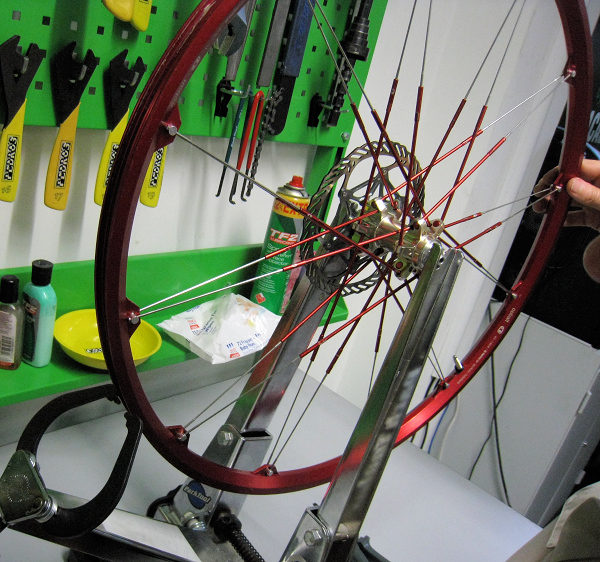

Before long we were marking, cutting and filing the tubes and tacking our frames up in the jigs. The jig, custom made by Chris Sheppard, holds all the tubes in exactly the right place as they are tacked together.

It was not until the final day that the frame itself was brazed. This was all done in one process to avoid multiple heat cycles. After so much practice on scrap tubing and all the work that had gone into cutting and mitring the tubes to fit just right, it all came down to this last half hour. Andrew, a veteran of many builds knew exactly how to manoeuvre the hot frame around as I gradually worked the torch’s acetylene flame and the bronze filler rod around the joints.

The job doesn’t end with the brazing though. The frame alignment needs checking and adjusting if required, the head tube must be faced and reamed and the bottom bracket tapped and faced. Straightforward jobs with the workshop’s full complement of Park Tools. And with that the frame’s complete.

It’s not a super lightweight racer but it is robust, built to last in a tough environment. The rear dropouts are spec’d for 100 kg load! My frame has a unique code number so once it’s left Frome I should be able to track it and find out just where in the world it ends up.

The finished frame!

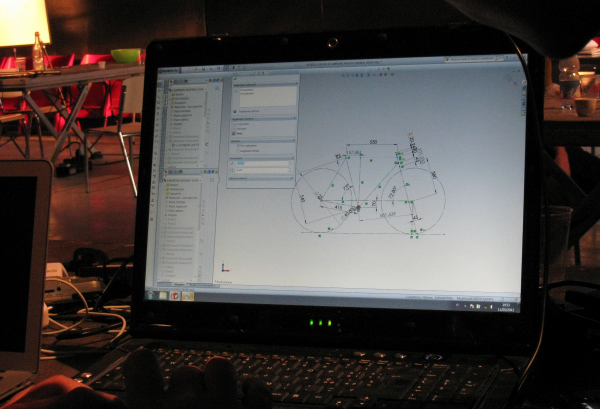

The week wasn’t all filing and brazing though. We also spent some time on the computer using

BikeCAD Pro which seems like a easy way to play around with designs before cutting the steel. Unique to The Bicycle Academy is that graduates (

wall of fame!) are able to return to the workshop and work on their own frame building projects, paying only for workshop time and materials. I’ll certainly be making use of this for my next project. Watch this space!

My finished frame - next stop Africa!

The Bicycle Academy schedule is currently full up, however, they will be taking new course bookings soon. Here’s the

waiting list form, fill it in and they’ll get back to you as soon as space is available.